Accurately locating buried utilities will help prevent costly damages as well as prevent the needless hassle. These five components can help ensure the locate is done accurately and efficiently.

1. The Wire

Using an extra high-strength copper-clad steel tracer wire can provide locators with an accurate read on the location and depth of the buried cable. Wire with a high carbon steel core, metallurgically bonded with a copper cladding, that is uniform and continuous, creates a bi-metal conductor that acts as one and is corrosion resistant.

Not only are these systems easy to install and necessary for accurate underground pipe detection, but they are also:

- Corrosion, moisture, chemical, oil, impact, crush, and abrasion-resistant

- Carry a much lower theft value than copper wiring systems

- Comes in sizes ranging from 14 through 6 AWG

- When grounded with a magnesium ground rod, corrosion is redirected to the ground rod, thus preserving the integrity of your tracer wire system

- Depending on the type of tracer wire you use, the break strength FAR exceeds typical copper applications:

- HF-CCS (High Flex)- 43% higher in strength than copper tracer wire

- HS-CCS (High Strength)- 227% the break load of copper tracer wire

- HDD-CCS (Directional Drilling)- 700% the break load of copper

- Considerably lower in cost and excellent price stability compared to copper counterpart

2. Test Station

2. Test Station

Test station marker posts are essentially a two-for-one: they provide easy access to tracer wire for locate technicians, as well as provide a highly visible and effective warning message to potential excavators.

Oftentimes, tracer wire is poorly maintained or exposed to the elements. An above-ground test station like the Rhino TriView™ Test Station and its friction-fit cap protects both the tracer wire and access terminals from severe weather and vandalism.

In areas where upright marker posts are not practical, the Rhino HideOut™ Test Station is an ideal choice. The flush-mounted test station can be mowed over while still providing a visible warning. It has a telescoping terminal board for quick access to the tracer wire.

3. Hardware

Locating multiple utility lines can become a tedious task for the locator – having to locate lines separately and continuously reconnect to the different terminals.

Innovative hardware like the Iso-Switch, can significantly speed up the locating process as it allows the locator to connect to all the facilities at once.

4. Ground

4. Ground

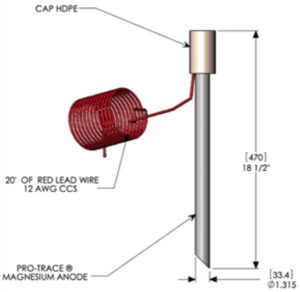

Grounding anodes should be installed at all dead ends of the tracer wire system to complete the electrical circuit needed to enhance the signal for locating purposes. Grounded tracer wire allows for the locator to use a lower frequency which provides the most accurate results for locating. Higher frequency has a tendency to bleed-over into other buried utilities, making the locate inaccurate.

The best way to ground a tracer wire system is to install a 1.5 lb. drive-in magnesium ground rod and an access point at each tracer wire dead end. An access point will protect the wire and provide a direct connection point for a utility locate transmitter to connect to the tracer wire. It also provides a connection point for the ground rod wire and allows the ground connection to be turned on and off, allowing you to control the signal on the target line.

5. Connectors

A tracer wire system is only as good as its weakest connection. Connectors with superior strength that are water and corrosion-proof protect vulnerable wire splices and keep the locate signal flowing across connections.

Using cheap alternatives like electrical tape will result in corrosion. A corroded connection point can cause the locate signal to stop at the connection point, making the rest of the buried utility unlocatable, which could end in disaster for the excavator.