What is FRP?

FRP is a Fiberglass-Reinforced Plastic material that has the strength of steel at the fraction of the weight. FRP won’t corrode, rot, warp, attract insects, or rust, making it an ideal and long-lasting replacement for steel, wood and aluminum in a wide range of applications.

Because FRP is a composite material made up of fiberglass reinforcements and polymer resins, FRP can also stand for Fiberglass-Reinforced Polymer. The glass fiber provides the strength and stiffness, and the resin provides shape and protects the fibers.

FRP is a common reinforcement to provide strength and durability in fiber optic drop cable. However, you have a choice of strength members for optical cable, and steel is also a consideration.

Let’s compare FRP with Steel as a strength reinforcement in fiber optic cable:

| Parameter | FRP Composites | Steel |

| Corrosion, rot and and insect resistance |

Resists a broad range of chemicals and is unaffected by moisture or immersion in water. Resists insect damage. Painting is only suggested when exposed to UV rays/direct sunlight. |

Subject to oxidation and corrosion. Requires painting or galvanizing for many applications. |

| Strength | Has greater flexural strength and pound-for-pound is often stronger than steel and aluminum in the lengthwise direction. |

Homogeneous material |

| Weight | Weighs 75% less than steel and 30% less than aluminum |

Could require lifting equipment to move and place |

| Electrical conductivity | Nonconductive High dielectric capability |

Conducts electricity Grounding potential |

| Thermal properties | Good insulator with low thermal conductivity |

Conducts heat |

| Stiffness | Will not permanently deform under working load. Modulus of elasticity: 2.8 x 106 psi |

Modulus of elasticity: 29 x 106 psi |

| Impact resistance | Will not permanently deform under impact. Glass mat in pultruded parts distributes impact load to prevent surface damage, even in subzero temperatures. |

Can permanently deform under impact |

| Color | Color is molded within No painting required |

Must be painted for color, may require repainting over time |

| Cost | Lower installation costs, less maintenance and longer product life allow for a lower lifecycle cost. |

Lower initial material cost More expensive to maintain Much higher over time |

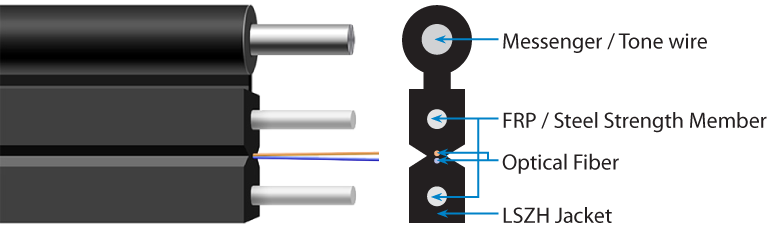

Where does FRP Strength Members fit into Fiber Optic Drop Cable?

FRP reinforcement is not the messenger, but in a common configuration will straddle the optical cable within the jacket. In the case of Multicom fiber optic cable, we have constructed our cable in such a way that the optical fiber has the absolute least exposure and the FRP strength members are in a position to guard the hair-thin optical cables to keep them out of harm’s way.